Extruded Holes

What are Extruded Holes?

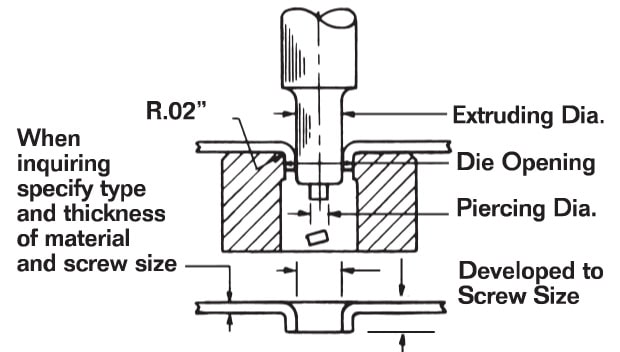

UniPunch tooling can be used to simultaneously punch a hole and extrude the material down. Applications include for self-tapping sheet metal screws or, in thicker material, to permit tapping for machine screws. Die buttons with oversized internal diameters, typically with a .020″ radius instead of a cutting edge, are used to permit the material to flow downward and punch an extruded hole. This technique can be used in any UniPunch unit to make relatively shallow extrusions; to accommodate deeper extrusions with standard UniPunch tooling, the Feed Clearance Unit (“FCU”) may be required so the part can be removed after forming. When placing an order or requesting a quote, please specify type and thickness of material and screw size.