Elevate Your Manufacturing with UniPunch’s Cluster Tooling

What is Cluster Tooling?

Cluster tooling is a punch, stripper and die with multiple points. This style of tooling allows multiple holes to be punched simultaneously with a single stroke of the press. This technique is particularly useful for parts that require a high density of holes close together. By grouping several punches together in a “cluster,” manufacturers can significantly reduce the number of press strokes needed, leading to faster production times and lower costs. Depending on the application, UniPunch will design a one-piece solid punch or a punch with replaceable tips.

Key Advantages

- Increased Efficiency: Punch multiple holes in one stroke, significantly speeding up production.

- Precision: Consistent force ensures uniform hole sizes and spacing.

- Versatility: Customizable to various patterns and hole sizes, suitable for different industries.

- Cost-Effective: Reduces the need for individual c-frames, lowering tooling costs.

- User-Friendly: Designed for quick setup and easy changeovers.

Applications of Cluster Tooling

Cluster tooling is versatile and can be used in various industries, including:

- Automotive: For components like heat shields, acoustic panels, and ventilation systems.

- Electronics: In the production of panels, enclosures, and cooling systems.

- HVAC: For creating perforated sheets used in heating and cooling units.

- Architectural: In the fabrication of decorative panels, cladding, and sunscreens.

Interested in learning more? Contact UniPunch today and discover how our cluster tooling solutions can elevate your manufacturing efficiency.

Efficiency Unleashed: Cost-Savings with UniPunch Tooling

Seamless Integration into Existing Processes

UniPunch tooling solutions are engineered to seamlessly blend into existing manufacturing setups, enhancing efficiency without the need for complete overhauls. Our systems can adapt to various production environments, ensuring a smooth transition and immediate improvement in setup and production times.

Customer Triumphs and Tangible Returns

Our clients, from Special Purpose Vehicles Manufacturers to High-Quality Lock Sets producers, have documented remarkable savings and productivity gains. For instance, one manufacturer halved their steel inventory, saving $5 million annually and doubling output. These success stories underline not just cost savings but also the strategic advantage of moving to Just-In-Time manufacturing. The typical return on investment (ROI) for UniPunch tooling is compelling, with many customers seeing significant operational savings that quickly offset the initial investment, often within months.

Customization Meets Manufacturing Needs

UniPunch tooling is incredibly versatile. Whether it’s adapting to specific materials or unique part configurations, our tooling is designed to meet your precise manufacturing needs. This customization helps you put holes in small intricate parts and heavy channel. Our team designs turn-key tooling systems to meet your hole punching needs.

The Future with UniPunch: Efficiency and Flexibility

Running UniPunch tooling isn’t just about enhancing current operations; it’s about minimizing waste and keeping production flexible. With UniPunch, you’re not just choosing a punching system but selecting a partner dedicated to providing the fastest and most efficient ways to punch and notch parts.

By integrating UniPunch tooling, you’re streamlining your production and boosting your efficiency.

Maximizing Tool Performance with Routine Punch and Die Replacement

In the fast-paced world of manufacturing and metal fabrication, maintaining tooling in peak condition is vital. Regularly replacing punches and dies is not just maintenance; it’s an investment in quality and efficiency.

The Case for Routine Replacement

Punches and dies undergo significant wear and tear, in time leading to decreased performance. By routinely replacing these components, you ensure consistent product quality, reduce machine strain, and avoid unexpected downtime.

Advantages of Keeping Tooling Updated

- Quality and Precision: New punches and dies ensure your products meet your stringent quality standards.

- Efficiency and Economy: Sharp tooling operates more efficiently, reducing energy consumption and wear on machinery, translating into savings and extended equipment lifespan.

- Operational Reliability: Regular replacement minimizes the risk of tooling failure, ensuring uninterrupted production schedules and customer satisfaction.

Why UniPunch Stands Out

UniPunch is your go-to source for high-quality hole punching, offering a broad selection to meet your part producing needs. Our commitment to precision, ease of ordering, and engineering support ensures you get the best tooling solutions promptly.

Order replacement punches and dies on order.unipunch.com today!

UniPunch Hole Punching Over Drilling

In metal fabrication, creating precise holes is a critical task. While there are various methods available, UniPunch tooling stands out for its efficiency and versatility, especially compared to traditional drilling.

Material Versatility

UniPunch tooling is exceptional in its ability to handle a diverse array of materials. It efficiently punches through:

- Mild Steel (up to 3/4″ thickness)

- Aluminum

- Stainless Steel (up to 1/4″ thickness)

- Copper

- Brass

- A36

- Composite, laminated materials, fiberglass, plastic, rubber

This wide range of compatibility outshines traditional drills, which may struggle with certain thicknesses or material types.

Precision

UniPunch tooling guarantees precision and consistency in hole quality. With its custom-made tooling, it ensures uniform holes across various materials, an aspect where drilling can sometimes falter, especially on a large scale or with difficult materials.

Efficiency

Speed is a significant advantage of UniPunch tooling. It can punch holes in a fraction of the time it takes to drill them, especially beneficial in projects with a high volume of holes. This efficiency can greatly accelerate project timelines.

Custom Hole Punch Designs

When it comes to cutting precise shapes out of metal, UniPunch custom hole punch designs provide an efficient and cost-effective solution.

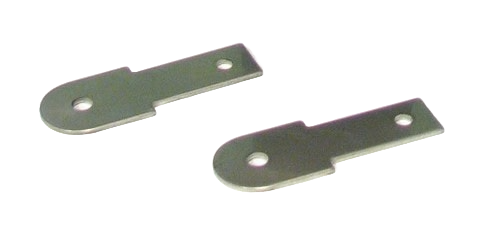

What is Blanking?

Blanking is the process of cutting a desired shape out of a flat piece of sheet metal. UniPunch tooling is used when the punch slug serves as the blank itself. Interestingly, a well-made punched hole has two sizes: the size of the punch on the entry side and the size of the die on the other side of the material. In blanking, it is the size of the blank that is crucial. The blanking die is made to size, while the punch is intentionally undersized to provide the appropriate punch and die clearance.

Benefits of UniPunch Custom Hole Punch Designs

Precision and Efficiency:

UniPunch designs ensure accurate and consistent blanking results, meeting the exact shape and size requirements of your application. This precision eliminates the need for additional machining processes, saving time and reducing costs.

Customization:

UniPunch understands that every application is unique. Their team of experts works closely with customers to develop custom tooling solutions, taking into account specific material thicknesses, hole sizes, die clearance, and production requirements.

Cost Savings:

UniPunch’s lower-cost alternative to traditional die sets significantly reduces tooling costs, making it an attractive option for small part production or combined blanking and punching operations. Additionally, UniPunch’s efficient tooling systems minimize material waste, further enhancing cost savings.

Streamlined Operations:

UniPunch’s turn-key systems simplify the blanking process, from setup to production. With integrated mounting systems and gauging, their solutions enhance productivity and minimize downtime between operations.

Create Hole Patterns With UniPunch Tooling

Are you looking to streamline your hole punching and part notching processes? Look no further than UniPunch. Our innovative tooling system offers a range of units that can be used together to create precise hole patterns and edge notches, making the production of parts faster and more efficient.

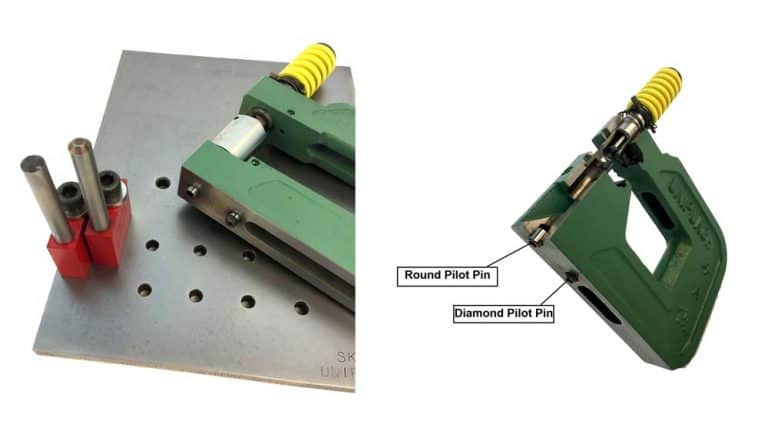

Create a Hole Pattern in Parts

The UniPunch system is designed to simplify the creation of hole patterns. With its c-frame casting and precisely aligned punch and die, you can achieve accurate results. The key to creating the desired hole pattern is the round pilot pin located at the bottom of the unit. By inserting it into the designated hole in the mounting system, such as a mounting template, you can easily achieve the desired outcome.

But what if you require a shaped hole? UniPunch has got you covered. An additional diamond pilot pin, also known as an orientation pin, maintains the orientation of the shape within the hole pattern. This ensures consistency across multiple batches of parts. The UniPunch system empowers you to create complex hole patterns without sacrificing accuracy or efficiency.

Embrace UniPunch for Enhanced Efficiency

The UniPunch system offers a host of advantages that can significantly enhance your manufacturing processes. Its ability to create precise hole patterns, combined with its rapid setup time and increased production speed, make it a game-changer for businesses aiming to improve efficiency and productivity.

Whether you are looking to streamline your existing operations or stay ahead of the competition, UniPunch can help you achieve your goals. Say goodbye to tedious setups and hello to a more efficient and productive future.

Your Trusted Solution for Efficient Hole Punching

At UniPunch, we are committed to providing you with reliable, high-quality tooling solutions for your hole punching needs. In this edition, we wanted to share a success story from one of our satisfied customers who experienced the convenience and efficiency of our UniPunch tooling.

Efficiency Boost in the Garage Door Industry with UniPunch Tooling

A leading garage door manufacturer recently shared their positive experience with UniPunch tooling. They rely on our tools to punch holes in the interior skins of their doors, enabling precise positioning of hinges during installation. By integrating UniPunch into their rollform line, they achieve improved efficiency as the steel is punched right after it comes off the coil. This setup streamlines their installation process, ensuring top-quality doors for their customers.

Simplified Ordering Process and High Flexibility

At UniPunch, we strive to make your experience as seamless as possible. Our customer praised the simplicity and efficiency of our ordering process. With a user-friendly interface, you can effortlessly select and customize the tooling you need, saving valuable time and effort.

Moreover, our tooling offers exceptional flexibility, adapting to your unique requirements. Our customer highlighted how our tooling seamlessly fits their needs, allowing for a hassle-free setup when working on their punched parts.

Discover UniPunch’s Stripping Spring Units

Are you looking to optimize your die sets for enhanced performance and increased productivity? Look no further than UniPunch’s cutting-edge Stripping Spring Units. In this comprehensive blog post, we’ll explore the remarkable benefits of these innovative units and how they can revolutionize your die design. Get ready to unlock a whole new level of efficiency and precision!

Understanding Stripping Spring Units

These specialized components, offered by UniPunch, are designed to provide precise, controlled stripping forces during the die-cutting process. They ensure effective removal of the part from the punch, eliminating the risk of jamming or misalignment.

Improved Die Set Efficiency and Performance

One of the primary benefits of UniPunch’s Stripping Spring Units is the remarkable improvement in die set efficiency. By utilizing these units, you can achieve faster cycle times, reduced downtime, and increased production rates. The controlled stripping force ensures smooth and reliable ejection of parts, minimizing the need for manual intervention and boosting overall efficiency. With their precise and consistent stripping forces, these units minimize the chances of part deformation, ensuring high-quality, accurate cuts every time.

Versatility and Compatibility

UniPunch understands that die sets come in various shapes and sizes. That’s why their Stripping Spring Units are designed to be versatile and compatible with a wide range of die designs. Whether you’re working with progressive dies, blank dies, or forming dies, UniPunch has the perfect solution to seamlessly integrate their Stripping Spring Units into your specific die set requirements.

Longevity and Durability

Investing in UniPunch’s Stripping Spring Units means investing in durability and longevity. Crafted with high-quality materials and precision engineering, these units are built to withstand rigorous and repetitive die-cutting operations. You can rely on UniPunch’s Stripping Spring Units to deliver consistent performance, ensuring longevity and minimizing the need for frequent replacements.

To learn more about UniPunch’s Stripping Spring Units and find the perfect fit for your die set, visit here.

**Survey discount offer will discontinue upon the completion of three respondents**

Shop UniPunch Online: Fast, Easy, & Convenient!

You can purchase UniPunch tooling and replacement parts online through our user-friendly online store!

Whether you’re a seasoned UniPunch user or new to our products, our online store offers a convenient way to browse and purchase the tooling you need for your manufacturing needs. With just a few clicks, you can easily find and order the parts and units you need to keep your operations running smoothly.

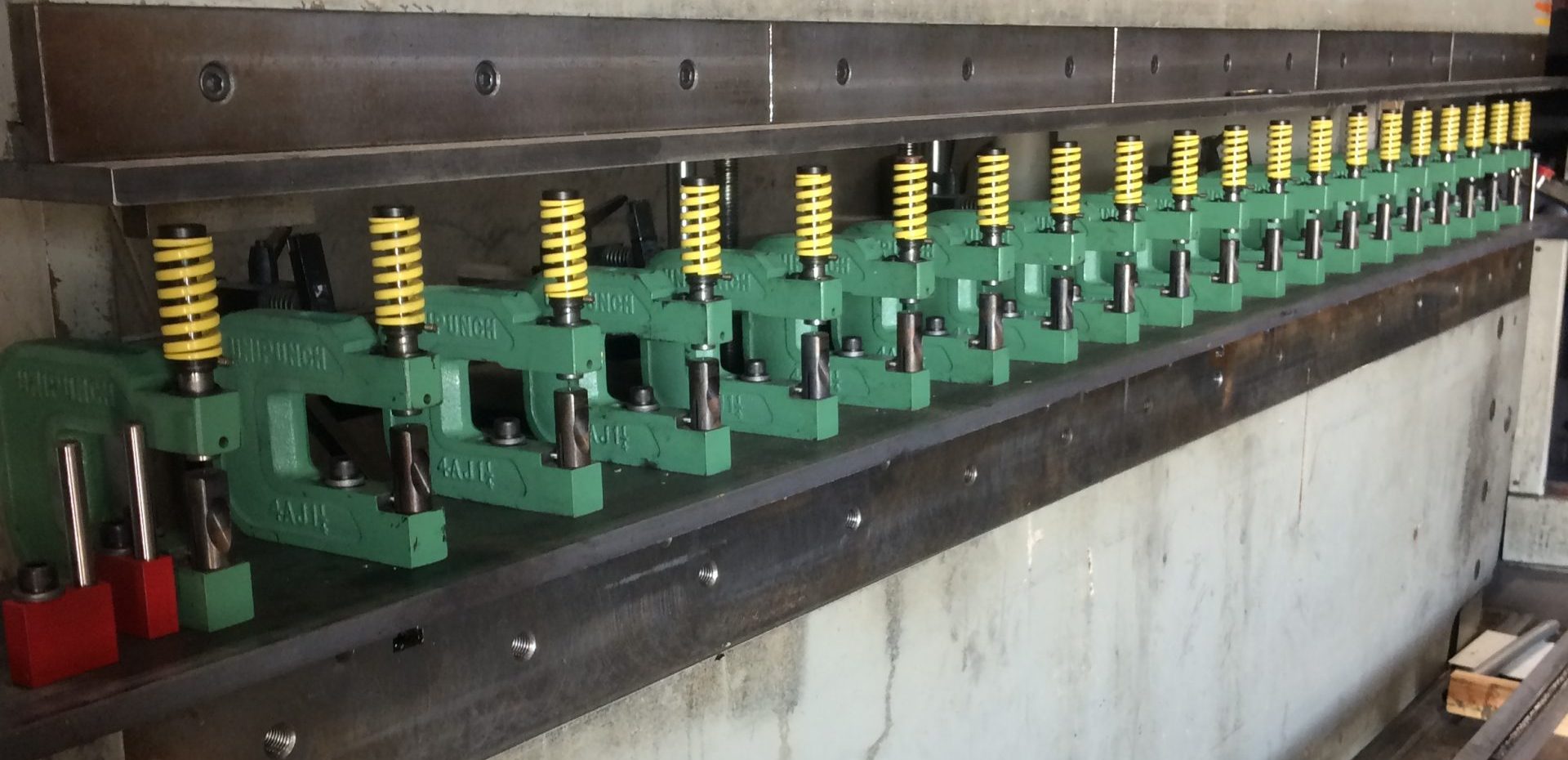

Update on Punching Holes in Aluminum J Channel

Three years ago, Lansing Housing Products, reached out to UniPunch looking for a solution to punch holes in a narrow aluminum profile. The holes, which are for installation purposes, were needed in their Tough Tek Metals® product. UniPunch was able to help with reduction of time and material handling. They have cycled several thousand parts and have had no issues with the punches. They are planning on working with UniPunch in the future on new projects.