Countersinking

What is Countersinking?

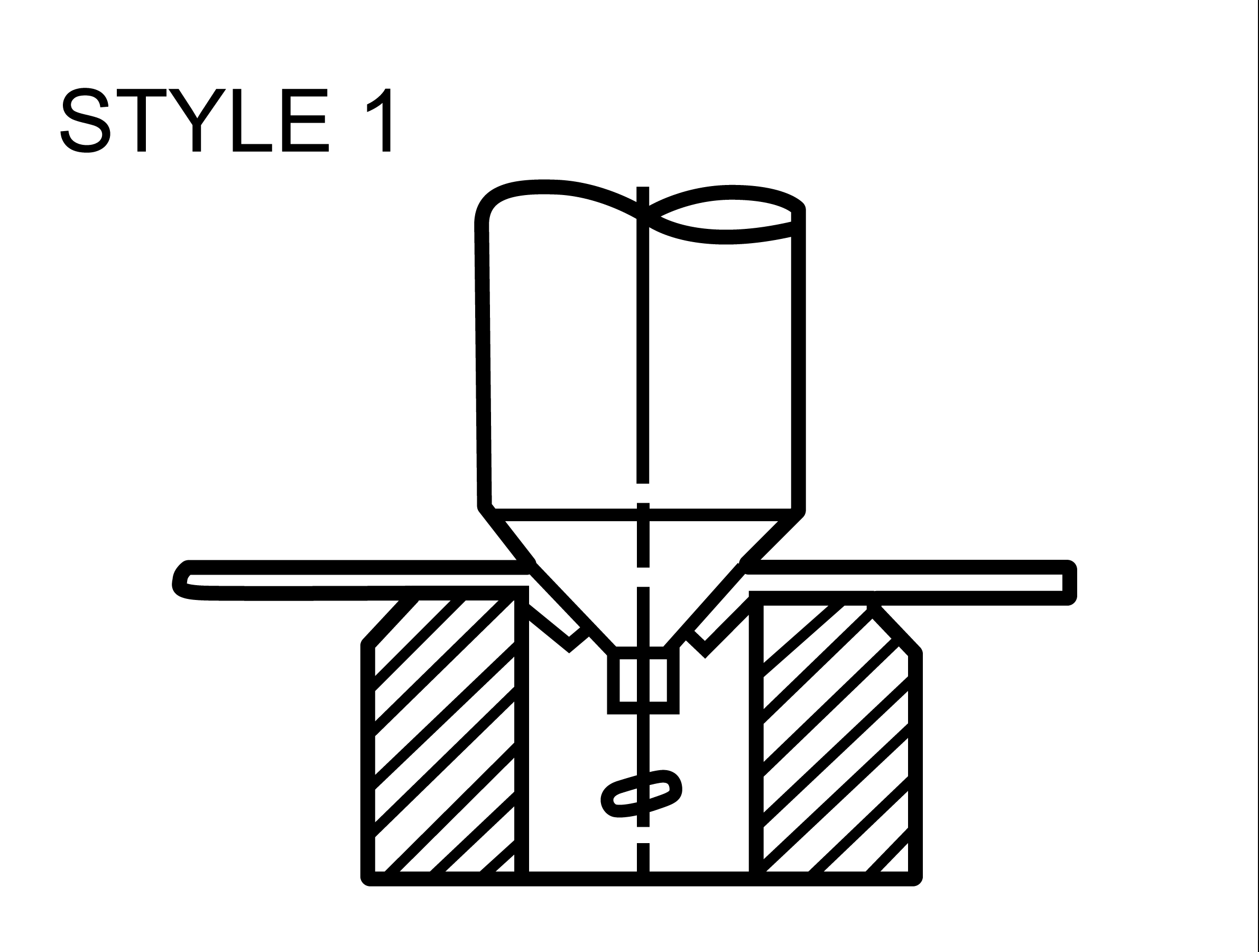

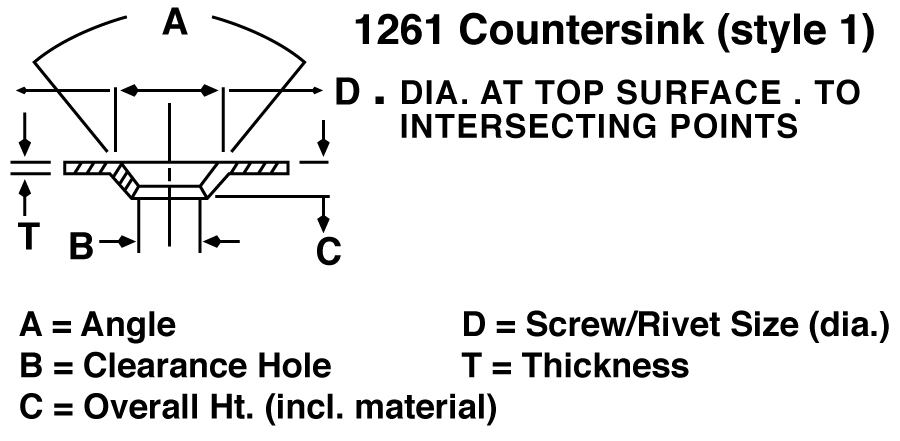

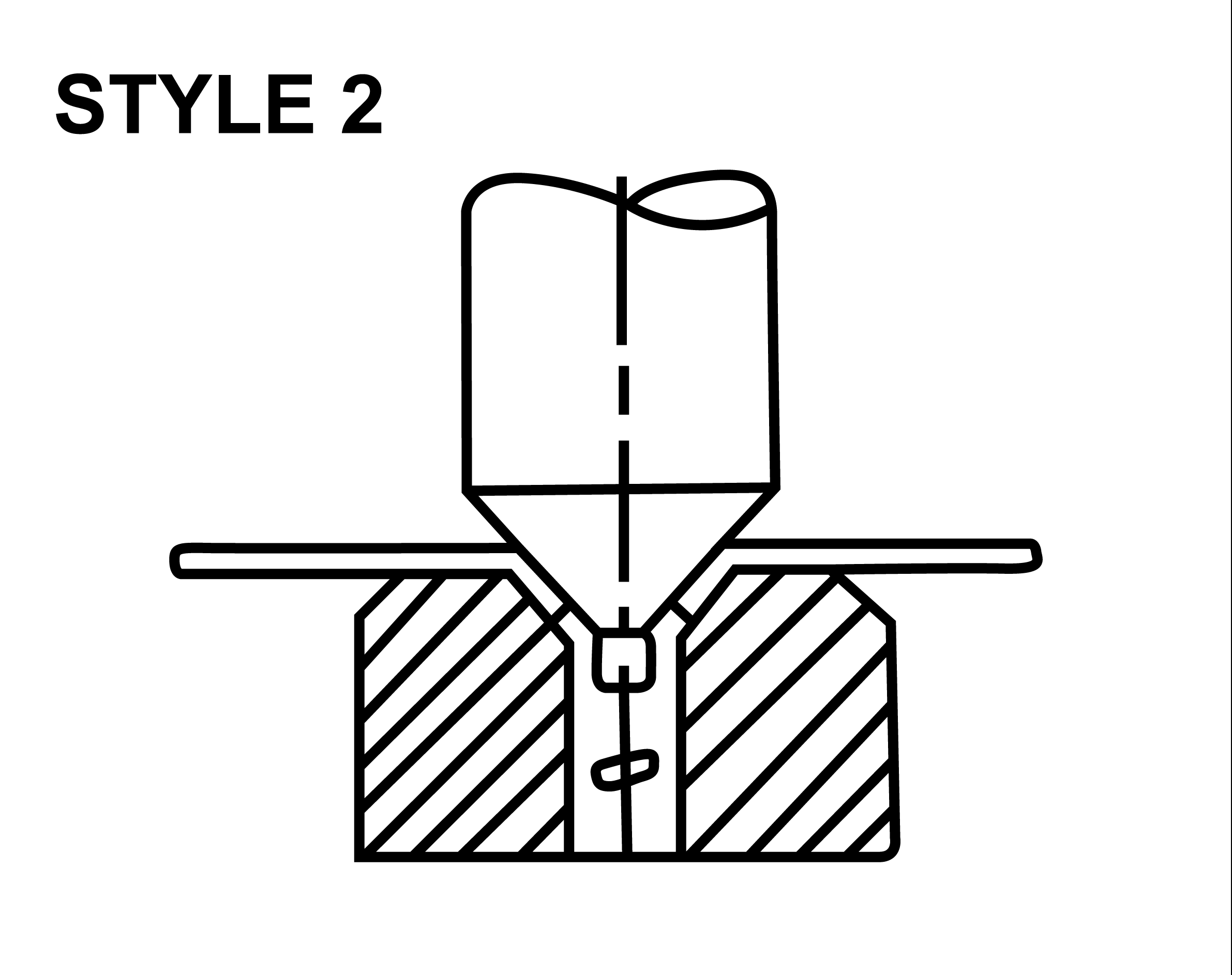

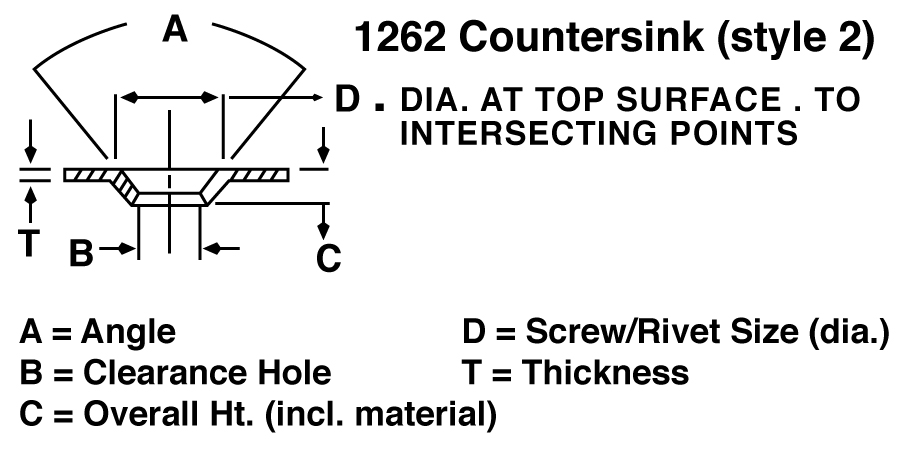

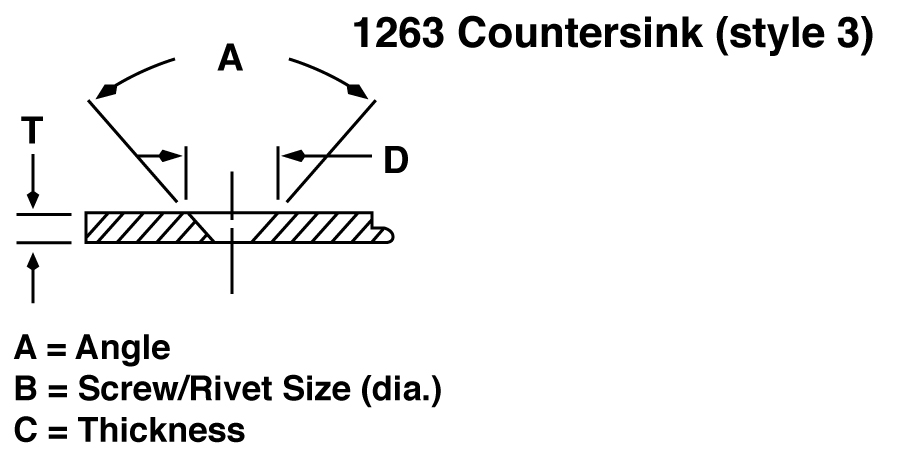

Countersinking is commonly used for holes that need to accept a flat head screw or fastener. We offer 3 different styles of countersinking which is shown below. When placing an order or requesting a quote, please specify the required dimensions based on the diagrams shown on the right side of the picture for each style.

How UniPunch Tooling Works:

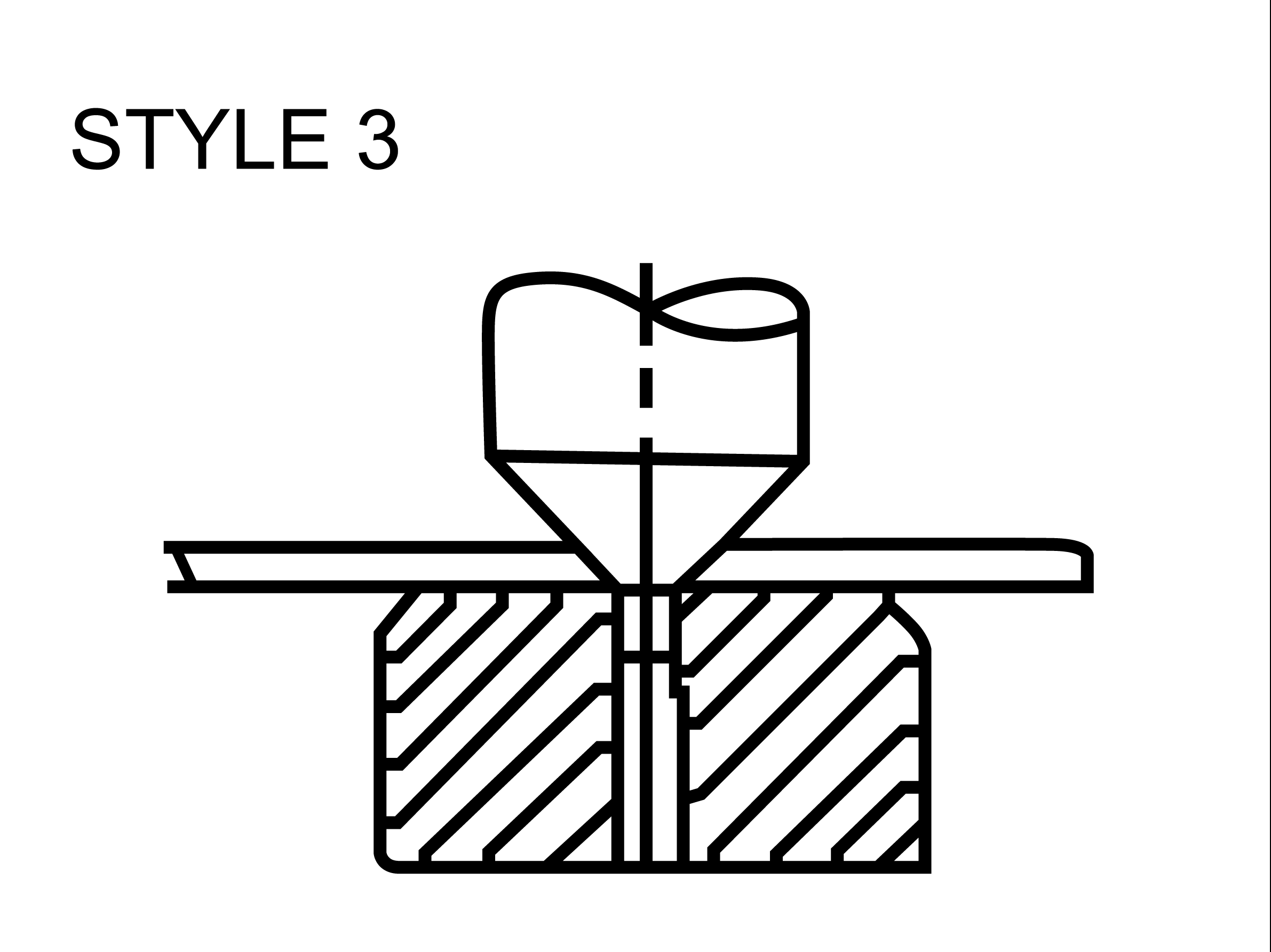

Countersinking Punches with standard open Die Buttons as illustrated to the left are used in “A” or “B” series units for countersinking up to 10 gage mild stell to accept flat head screws. Die Buttons have 1/32″ radius instead of cutting edge. “A” series units with adjustable feed opening are recommended for easy removal of formed workpiece. The “B” unit feed clearance must be increased for removal of formed workpiece.*

The Die shown at left allows the Punch to bottom the countersink shape into the workpiece at the bottom of stroke. This Die provides a more unifor countersink.*

The machined type of countersink is used in “A” or “B” series standard units for countersinking up to 10 gage material. The Die shown at the left allows the Punch and Die to bottom the countersink shape into the workpiece at the bottom of the stroke.*

Due to the nature of this style, material will deform and a burr will occur. The amount will vary according to material and specifications.

EXAMPLES

Style 3 Countersink

*NOTE: all the above mentioned Countersinking Punches and Dies are bottoming operations and extreme caution must be taken in setting the proper shut height. Prices are available upon request from UniPunch Products Quotation Department. Specify size of screw, type of material and thickness when inquiring.

Above is one of our customers countersinking 5/16 holes with UniPunch.