Lubrication

The following series of photos illustrates what components to lubricate during normal tooling maintenance and assembly. For this example, the UniPunch 8AJ-1 ½ unit is shown.

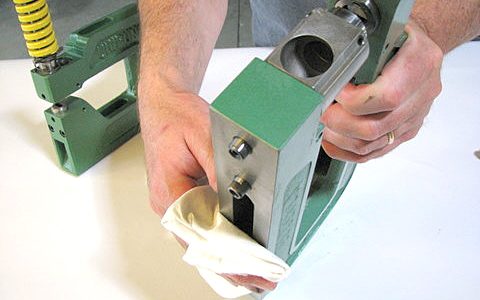

1: Disassemble unit. Clean and inspect internal components.

2: Externally lubricate outside diameter of guide body. Type GN metal assembly paste or die grease is recommended.

3: Reassembly of UniPunch unit. Place conical lifter spring over outside of guide body.

4: Reassemble guide body with lifter spring into holder guide bore.

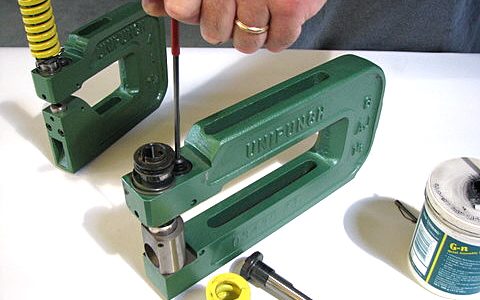

5: Align guide flat with retainer flat in holder.

6: Secure retainer and guide with fastener.

7: Insert punch body into stripping spring.

8: Externally lubricate punch body with Molykote GN metal assembly paste.

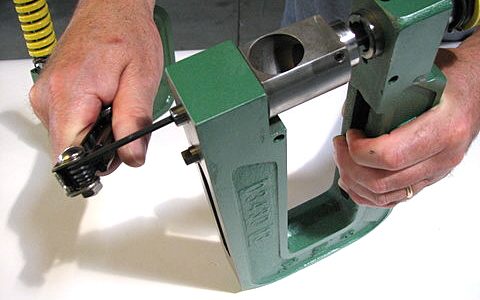

9: Align punch flat with retainer pin hole in guide. Insert punch retainer pin.

10: Tighten die fastener with hex key wrench.

11: Check pilot pin die adapter fastener, securing it to holder.

12: Wipe all debris from bottom of unit machine surface before mounting.