The Fastest Way to Punch Holes in Steel

Increase production speed right away and reduce labor costs with tooling designed to quickly punch multiple holes within seconds.

Rapid & Durable Hole Punching in Steel:

The UniPunch steel punch systems are designed to give you the speed you need to cut labor costs and improve efficiency. The tooling can punch holes in stainless steel up to 1/4″ thick. D2 tool steel reduces wear on punches and increases longevity. UniPunch also provides shear and back taper on punches to reduce stripping pressure.

The UniPunch steel hole punching tooling will punch mild steel up to 1/2″ thickness. The punches are made from A2 tool steel for longevity.

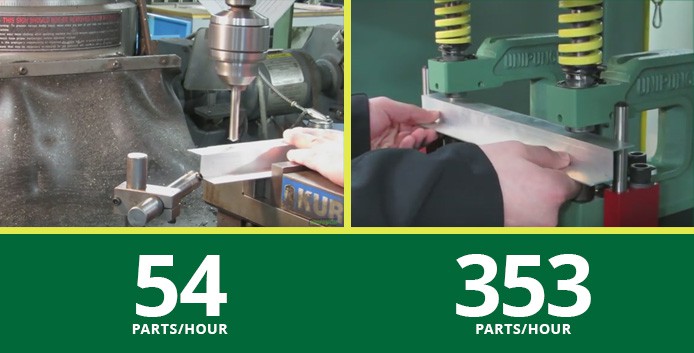

- Fastest Production Speed

Punch more holes in steel parts per hour. If you’re finishing 400 parts in a day now, imagine 2,400 instead. - Faster Into Production

We can provide most UniPunch tooling within days, so there’s no need for you to wait months. - Faster Setup Time

Faster changeover from part to part.

See how one client increased their speed from 20 parts a day to well over 100.

Tell Us About Your Job. We’ll Help You Make Holes Fast!

Our experts have helped thousands of manufacturers increase their speed of production.

Call us at 1-(800)-828-7061 or fill out the form below, and our team will recommend the right UniPunch solution for your needs.

Available Shapes

Punch a variety of shapes in stainless steel and mild steel. Have a custom shape in mind? No problem. We can customize our punches to fit your needs.

How It Works

UniPunch uses C-Frame technology to rapidly punch holes in stainless steel and mild steel. See how this unique system works along with its easy operation.

Why Choose UniPunch?

With a UniPunch, you get speed, ease of use and rapid changeover that other companies can’t match. Discover seven ways we outpace other tooling.

Punching Steel with UniPunch

Versatility matters just as much as speed. We’ve spent over a half century improving the efficiency of our systems while growing their capabilities. Get the right tooling for punching mild steel, stainless steel or sheet metal today. Check out the types of punches our systems can make in steel materials.

Manufacturers Love Saving Time with UniPunch

Here is what just a few of them had to say:

“When I came in, they didn’t know about UniPunch. It used to take them three weeks to complete 300 locks…now we’re making 600 in one week just because I knew about the UniPunch system and was able to teach them how to use it and pick up our production.”

– Lock Set and Door Hardware Manufacturer

“The operators like working with the tooling. Once it’s set up and you have your template made, it’s a breeze…just a snap.”

– Dave,

Engineering Manager

The Metalworking Group

“Without costing an arm and a leg, there is just no other way to do it. The labor would be outrageous.”

– Tim,

Tooling Designer

Cooper B-Line

Punching Steel Case Study

Like many of UniPunch’s customers, J & S needed to improve efficiency and uniformity in their manufacturing process. They had relied on an ironworker. This was a slow, painstaking process of making only one hole at a time. After making each hole, they would then have to measure the distance out between the next, which added to the time per part and opened up their process to human error. After receiving their UniPunch systems, they were able to quickly and accurately punch a number of holes in their steel verticals within seconds.

Start Your Success Story Today!

Increase throughput on your steel parts today with our unique punching solutions. Give us a call at 1-877-832-9034 or fill out a quote request and our team will recommend the right UniPunch solution for your needs.