10x Faster than Drilling

A manufacturer of garage storage systems significantly increased production with UniPunch.

The Challenge

“Drilling holes became too slow for us. Rhino Shelf is a fast-growing, high-quality company and product. We are committed to being American-made and holding ourselves to the highest standards of quality and performance. UniPunch seemed to share that commitment, so we reached out to them to create custom tooling for our parts.”

Working with UniPunch

“The entire process with UniPunch was excellent, from the first time we contacted them through delivery of the tooling. UniPunch’s team was FAST, EFFICIENT, and PROFESSIONAL. UniPunch’s communication was excellent. Drafts of our tooling were done quickly. We refined the drafts and, once finalized, the UniPunch system arrived at our facility. Setup for Unipunch was easy with our press brake.”

We can punch parts TEN TIMES faster than drilling

We can punch parts TEN TIMES faster than drilling

Speeding up Production

“Once we put UniPunch to work, we knew that we made the right decision. We can punch parts TEN TIMES faster than drilling. Before UniPunch, we had an extensive deburring process. That has now been eliminated. Most importantly, Unipunch is extremely SAFE. Our employees are the best and their safety is more important than any other function of the company. Drill presses can be unsafe in several ways, but our punching process is BY FAR the safer option.”

The Tooling Pays for Itself

“Safer, faster, more efficient. By our calculations, each setup pays for itself in 14 weeks.”

“We have now transitioned our most common parts to UniPunch tooling exclusively and, due to the excellent results that we’ve achieved, will be transitioning ALL of our parts quickly.”

“I want to thank Howard Stream and the entire UniPunch team for their attention to detail, their fantastic service, and their product that has revolutionized the way we manufacture Rhino Shelf – the best garage storage shelving ever made.”

Aaron B. Carter

Innovative Design Technologies, LLC

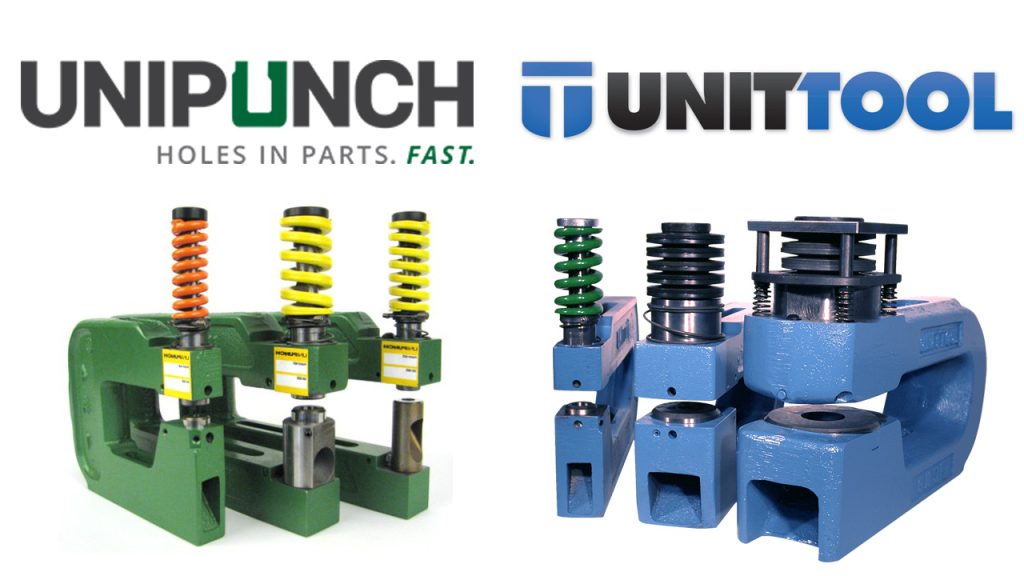

UniPunch and Unittool Have Joined Forces

Clear Lake, Wisconsin,

09/01/2022

UniPunch Products, Inc. and Unittool announced today that the brands will be combined to create the industry leader in C-Frame tooling.

“This collaboration between the brands has been a long time in the making,” said Jon Summers, president at UniPunch. “The friendly competition between Unittool and UniPunch has made both product offerings stronger over the years, and the added benefit of single-point manufacturing and sales support will enable us to serve the marketplace well for many years to come.”

Both brands have provided high quality punching, shearing and notching tooling for more than 60 years, with customers around the world. The combined reach of the two companies accounts for more than 95% of all C-Frame tooling purchased in North America.

“When my father started this business more than fifty years ago, his goal was to take care of his customers, his employees and his family” said Leonard Deni, president at Unittool. “We’re incredibly proud of his legacy, and that this partnership will continue that legacy.”

This initiative will merge the product offering, sales channels and manufacturing to efficiently serve the entire marketplace with both brands from a single location.

The manufacturing and sales support for the combined brands will be in Wisconsin.

Speed up Production

When Diversified Construction Co. needed a faster way to make holes in heavy channel, they chose the UniPunch system. With an ironworker, punching holes one-at-a-time was just too slow. Now using UniPunch, they punch a row of 9 holes in one stroke of the press! Diversified Construction Co. went from producing 20 parts per day to well over 100.

Before, with Ironworker:

After, with UniPunch:

How can we help you make holes faster?

Short Lead Times

In this new year, as we reflect on 2021, we cannot help but think of all the challenges the manufacturing industry has faced, especially supply chain issues.

It is important to us that our customers know that UniPunch tooling lead times remain short. Our products are made in the USA and ship fast from Wisconsin. We continually improve our machinery and manufacturing processes to increase production and provide a quick turnaround.

The vast majority of products ship within a couple days. When you need punches and dies, you can be confident that UniPunch will ship them fast!

NEW: Order Tooling from Our Shop

Shop for UniPunch Products at MSC

UniPunch tooling and components are now available for purchase through MSC Industrial Supply Co.

Click here to visit the UniPunch store at MSC.

The HZ-2 Horizontal Punching Unit is back!

Back by popular demand, UniPunch is once again offering the HZ-2 unit. The Horizontal Punching Unit is designed to put holes in the vertical sides of flanges, rims and formed parts. The HZ-2 unit can punch a 7/8″ diameter hole in up to 1/4″ thick mild steel. Contact us to learn more about how horizontal punching can help you make parts faster.

Eliminate Deburring and Speed Up Production

Switch from Drilling to Punching

When Echo, Inc. began punching aluminum and steel pipe shafts instead of drilling, they were able to eliminate the deburring process. Speeding up production time was important as Echo punches several different diameter shafts for commercial landscape equipment, including trimmers, edgers, power pruners and more. When it’s time to punch a different diameter, they simply swap out one UniPunch tool for another.

The UniPunch system is used to make thousands of different components and products every day. Manufacturers punching parts with C-frame tooling come from all different industries and the products range from hinges to lighting to truck trailers, to name just a few. Production speed and hole quality are important to our customers. That’s why they choose UniPunch.

What can we help you build? Contact us today!

Punching Exhaust Tubing

A manufacturer of exhaust systems utilizes UniPunch tooling to punch slots in tubing.

The purpose of the slots is to allow the tube to be assembled into the inside diameter of the muffler. In this case, the slot locations were not critical, but UniPunch does offer custom gauging for when precise locating is necessary. When you need to punch more than one size of tubing, UniPunch provides mandrel dies to fit each tube diameter.

Contact us for a quote today!

Less Time… More Parts. 2020 Update

In 2018, we talked to Jeff, a manufacturer of animal enclosures, who was punching flat bars one hole at a time with an ironworker. It was time consuming and the hole-to-hole accuracy was difficult to maintain. He started punching all of the holes in one hit with the UniPunch system and went from making 60 parts per hour to 600!

In early August 2020, Jeff called to buy more punches and reported that he had just finished a run of 1,900 verticals (the flat bars used for hog enclosures) and his UniPunch units were going strong.

Watch the video to learn more: