There are a variety of ways to reduce the required press tonnage.

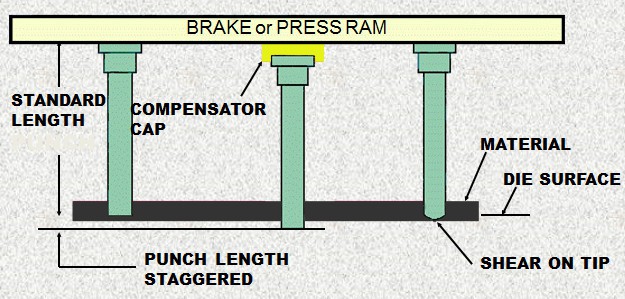

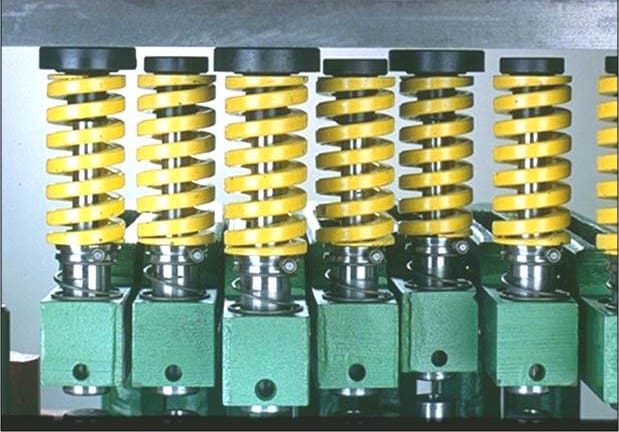

- Use Tonnage Compensator Caps – Stagger the punch length so that the punches pierce the material at different intervals

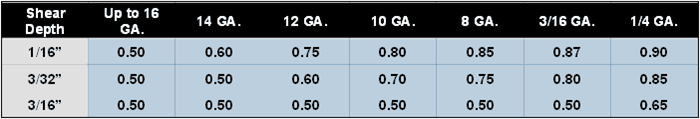

- Add Punch Shear – A shear angle ground onto the punch tip reduces the load or tonnage unlike flat faced punches

- Use correct die clearance – This results in a balance of punching force, good hole quality and increased tool life

- Sharpen punches & dies often

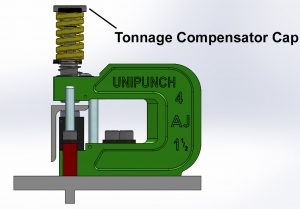

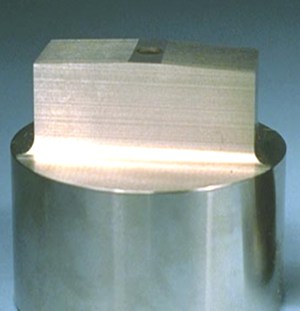

Tonnage Compensator Caps

Tonnage Compensator CapsAre your punching capabilities limited by the tonnage of your press or press brake? UniPunch has a solution. Compensator caps stagger the punch length so that the punches pierce the material at different intervals, reducing the required punching tonnage. They are fastened to the punch heads of “A” and “AJ” series units to reduce the total punching load required for multiple holes. Need help determining tonnage? Our press brake tonnage calculator can help you determine if caps are needed or additional tonnage is required.

| UniPunch Unit | Compensator Cap

Part Number

|

| A-1, A-1 1/4,

AJ-1, AJ-1 1/4 |

1040 |

| A-1 1/2,

AJ-1 1/2 |

1041 |

| A-2,

AJ-2 |

1042 |

For more information on tonnage, click here.

Punch Shear

Chisel shear on punches can considerably reduce required press tonnage. UniPunch offers Chisel Shear, 4-Way Shear and Concave Shear.

Chisel shear on punches can considerably reduce required press tonnage. UniPunch offers Chisel Shear, 4-Way Shear and Concave Shear.

Chisel Shear

4-Way Shear

Concave Shear